A pressure switch is a control device that detects changes in force and mechanically opens & shuts an electrical circuit at a predetermined point. Switches are more complicated than other coercion instruments, such as pressure gauges and sensors, which measure and monitor pressure. Knowing what is pressure switch is will help you understand its key applications, too.

Aims Controls, as the pressure measurement instrumentation industry leader. We came up with this blog to provide fundamental information about switches for those new to the business. Continue reading to discover about different types, what is their use, how they work, switch accuracy, activation methods, etc.

What Is a Pressure Switch?

A pressure switch is a mechanical or electronic device that activates when the process fluid’s force reaches a predetermined threshold or setpoint. It can be made of a bourdon tube, piston, diaphragm, or membrane that moves or deforms in response to the system’s force. For example, an air pressure switch is used to maintain a steady force and can turn off the compressor once the tank achieves the required air pressure level.

Pressure switches and transducers are not the same thing. The latter transfers pressure to an electrical output signal.

Types of Pressure Switches:

Mechanical pressure switch.

These switches are used for less complex applications since they are simple and durable. It use a spring and a piston to control the force at which they activate.

The spring is the force resisting the inlet pressure, and its tension can be modified using a set screw or knob. In turn, the spring pretension is precisely proportional to the pressure at which an electrical contact occurs.

When the force drops, the switch resets to its original state. It is more suited to handle high voltages and amperages than an electronic pressure switch. They can be used to increase or decrease coercion with a contact change.

Electronic pressure switch

Electronic pressure switches have a pressure transducer, usually a strain gauge, and extra electronics that convert signals into readable output. This one has numerous advantages over a mechanical pressure switch. Some of the benefits include increased precision, less contact wear, superior long-term stability, ease of use, and the ability to execute thousands of switching cycles.

How Does a Pressure Switch Work?

- Pressure is applied by a pressure source via the process connection.

- This pressure pushes the actuator (also known as the diaphragm) higher.

- However, an opposing force generated by the spring and adjusting nut prevents the actuator from going upward.

- To move the actuator assembly, the force from the pressure source must outweigh the opposing force from the spring.

- The Adjusting Nut controls the switch’s setpoint. When the adjusting nut is elevated, it reduces the force in the spring (reducing the set point). Lowering the adjusting nut increases the force in the spring (raises the threshold).

- When the force of the process pressure ultimately overcomes the force of the spring, the actuator will push higher, moving the push rod and changing the switch’s state.

Applications of Pressure Switches

- Air compressor pressure switches are used to monitor and control system air pressure in HVAC, gas cylinders, air pumps, and other applications.

- When the engine’s oil pressure falls below the preset level, oil pressure switches are utilized to detect the drop.

- A well pump pressure switch is used in both residential and commercial structures to pull water from the well and maintain enough water pressure in the system to give water without overpressing.

- Water pumps in residential, commercial, and agricultural settings employ switches to automatically adjust flow.

- A vacuum pressure switch detects the vacuum in the system or negative pressure. These components are used in boilers, electric heaters, air compressors, and gearbox systems.

Benefits of Using Pressure Switches

It provides several advantages, including pressure control automation, increased safety by preventing overpressurization, improved system efficiency through optimized pressure levels, dependability by reducing manual intervention, and the ability to trigger alarms or shutdowns when pressure exceeds safe limits, making them critical components in a variety of industrial and residential applications where consistent pressure is critical.

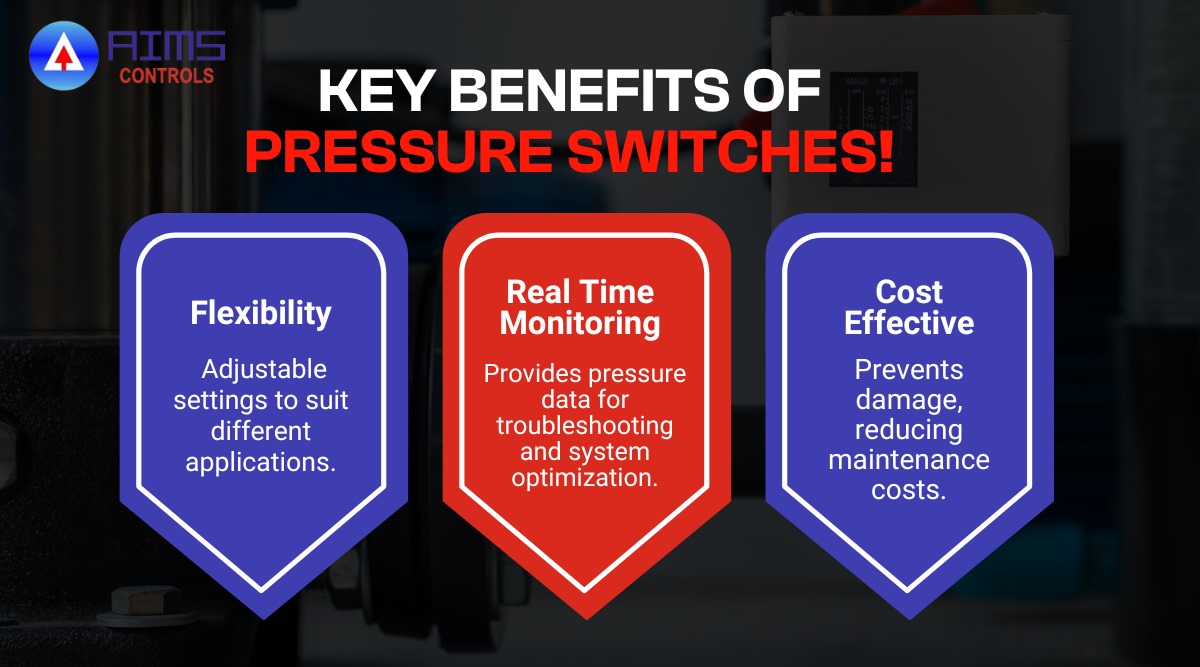

Key benefits of pressure switches:

- Automatic control eliminates manual pressure monitoring by automatically responding to pressure changes.

- Safety feature: Shut down systems at harmful pressure levels to prevent equipment damage.

- Improve energy efficiency by maintaining ideal pressure levels and minimising unnecessary system runtime.

- System Reliability: Reduce downtime by automatically responding to pressure variations, which eliminates the need for human adjustments.

- Flexibility: Adjustable pressure settings to meet individual application needs.

- Provide real-time pressure data for system monitoring and troubleshooting.

- Cost-effective: Prevent damage caused by excessive pressure, resulting in lower maintenance expenses.

Why Choose Aims Control for Your Pressure Switch Needs?

AIMS Controls has established itself as a trusted name in the instrumentation business via a continuous dedication to innovation and excellence. Our experience includes important areas such as oil and gas, petrochemicals, steel, cement, food and beverages, HVAC, pharmaceuticals, and more.

We are committed to addressing the most challenging technological challenges by providing high-quality, cutting-edge equipment and services at low costs, backed by a skilled workforce.

AIMS Controls proudly represents the official trademark of PI Controls Instruments Pvt. Ltd., which was formed in 2018. With a cutting-edge 3,500-square-foot production facility, we specialise in producing high-quality Process Control & Measuring Instruments.

Our vast product line includes pressure and temperature gauges and switches, temperature elements, level gauges, flow switches, instrumentation fittings, manifolds, valves, and a variety of accessories designed to fulfill a wide range of industrial needs.

Conclusion

We hope you now understand what is pressure switch and its uses. It is a type of switch that is actuated when the force of the process fluid reaches a predetermined threshold or set point. A pressure switch may include a bourdon tube, piston, diaphragm, or membrane that moves or deforms in response to the amount of pressure exerted by the system.

Ready to optimise your systems using high-quality pressure switches? Contact Aims Controls today to learn more about our products and how they may help your business.