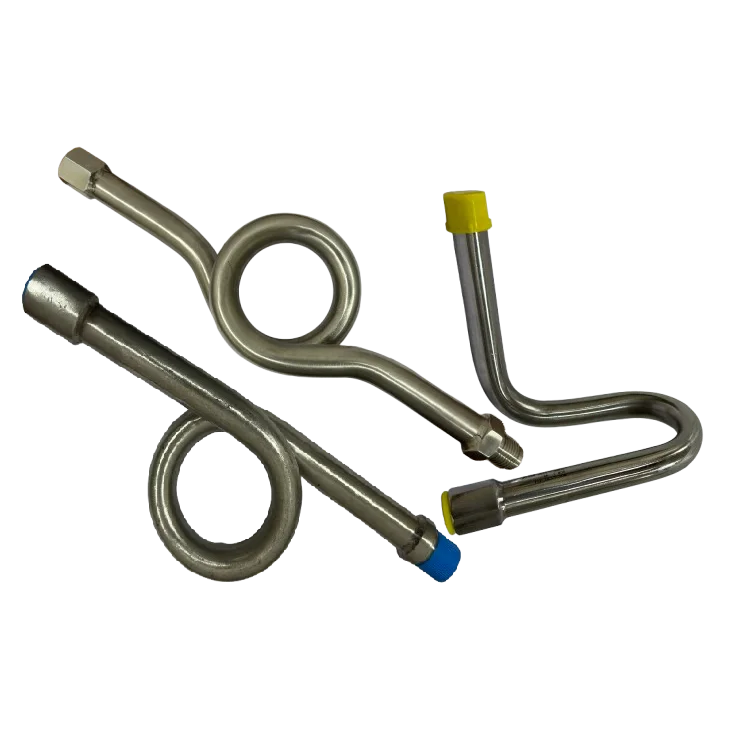

Quick connect/disconnect, laser-welded flush diaphragm, and mating parts are available in accessories.

- Range type: 0…1.6to 0…40 bar

- Standards: DIN 11854, SMS, RTJ/APV, IDF/ISS

- Wetted parts: AISI 316L SS

- Sealing fluid: Glycerine [10°C to 150°C]

- Assembly: Direct / Remote