Get A Quote

Become Distributor

Pressure

Pressure

- Home

- Pressure - Gauges Products

Gauges

ALL SS STANDARD PRESSURE GAUGE

All SS measuring system, Socket-case direct welded, Dry / liquid filled

Dial size : DN100 / DN125 / DN150 / DN250

Range : -1...0...1,600 bar

Process connection : ½" NPT (M)/½" BSP (M)

Ingress protection : IP65 / IP 68

Execution : Dry / Dry but fillable, glycerin

ALL SS ECONOMICAL PRESSURE GAUGE

All SS measuring system, Socket-case, direct welded, Dry / liquid filled

Dial size : DN50/ DN63 / DN80 / DN100 / DN150

Range : -1…400 bar (DN50), -1…1,000 bar (DN 63 / DN80 / DN100 / DN150)

Process connection : ¼" NPT (M) / ¼" BSP (M)

Ingress protection : IP 65 / IP 68

Execution : Dry / Dry but fillable, glycerin

ALL SS SOLID FRONT PRESSURE GAUGE

Safety pattern type, Solid front with full blow-out back, All stainless steel system, Dry / liquid filled

Dial size : DN100 / DN150

Range : -1...0...1,600 bar

Process connection : ½" NPT (M) / ½" BSP (M)

Ingress protection : IP 68

Execution : Dry but fillable, glycerin

ALL SS SOLID FRONT PRESSURE GAUGE

Safety pattern type, Solid front with full blow-out back, All stainless steel system, Dry / liquid filled

Dial size : DN63

Range : -1...1,000 bar

Process connection : ¼" NPT (M) / ¼" BSP (M)

Execution : Dry but fillable, glycerin

Ingress protection : IP 65

SOLID FRONT PRESSURE GAUGE (PHENOLIC)

Solid front with full blow back, Dry / liquid filled, Light weight, Stabilized accuracy

Accuracy : Grade 2A (± 0.5%)

Dial size : 4.5”

Range : -1...0...1,600 bar

Process connection : ½" NPT (M) / ½" BSP (M)

Execution : Dry but fillable, glycerin, IP 65

DIFFERENTIAL PRESSURE GAUGE (SINGLE DIAPHRAGM)

All SS measuring system, External Zero adjustment, Electric contact version, Dry / liquid filled

Accuracy : CL 1.6 & CL 2.5

Dial size : DN100 / DN150

Range : 25 mbar…0...16 bar

Process connection : ¼" NPT (F) x 2 Nos.

Ingress protection : IP 65

DIFFERENTIAL PRESSURE GAUGE (BELLOW)

All SS measuring system, Static pressure 40 bar max., External Zero adjustment, Electric contact version, Suitable for direct valve mounting

Accuracy : ±1.0 of FS (1 bar & above), ±1.6 of FS (below 1 bar)

Dial size : DN150

Range : 0...100 mbar to 0...16 bar

Process connection : ½" NPT (M) x 2 Nos.

Ingress protection : IP 65

DIFFERENTIAL PRESSURE GAUGE (PISTON)

Compact design, Migrated pressure chambers, Static pressure up to 200 bar

Accuracy : ± 2 % (Ascending)

Dial size : DN63 / DN100 / DN150

Range : 0...0.25…70 bar

Process connection : ¼" NPT (F) x 2 Nos

Ingress protection : IP 65

DIFFERENTIAL PRESSURE GAUGE (DIAPHRAGM)

Diaphragm operated, Compact design, Isolated pressure chambers, Static pressure up to 100 bar

Accuracy : ± 2 % (Ascending)

Dial size : DN63 / DN100 / DN150

Range : 0...75 mbar up to 0…4 bar

Mounting pattern : In-line connection

Process connection : ¼" NPT (F) X 2 Nos

STANDARD SWITCH CONTACT PRESSURE GAUGE

All SS measuring system, Socket-case direct welded, Liquid filled versions

Dial size : DN100 / DN150

Range : -1...0...1,600 bar

Switch : 1NO, 1NC, 1NO+1NC, SPDT, DPDT

Electrical termination : 4 pin PG 13.5 connector

Execution : Dry, IP 65

HI-CASE SWITCH CONTACT PRESSURE GAUGE

All SS measuring system, Socket-case direct welded, Liquid filled versions

Dial size : DN100 / DN150

Range : -1...0...1,600 bar

Switch : 1NO, 1NC, 1NO+1NC, SPDT, DPDT

Electrical termination : 4 pin PG 13.5 connector

Execution : Dry, IP 65

TRANSMITTER PRESSURE GAUGE

Solid front with full blow back, All stainless steel system, 4...20 mA transmitter output

Dial size : DN100 / DN150

Range : -1…0...600 bar

Process connection : ½" NPT (M) / ½" BSP (M)

Transmitter specification : 2 wire type,24 VDC, loop powered

Electrical termination : 4 pin PG 13.5 connector

ALL SS STANDARD CAPSULE PRESSURE GAUGE

All SS measuring system, Socket-case, direct welded, Low pressure application (<0.6 bar)

Accuracy : CL 1.6

Dial size : DN63 / DN100 / DN125 / DN150

Range : -600...25...600 mbar

Process connection : ½" NPT (M) / ½" BSP (M)

Ingress protection : IP 54

ALL SS DIAPHRAGM PRESSURE GAUGE

All SS measuring system, Socket-case direct welded, Threaded / Flanged connection

Dial size : DN100 / DN150

Range : 6... 40 mbar / 60...600 mbar / -1...0...25 bar

Process connection : ½" NPT (M) / ½" BSP (M)

Ingress protection : IP 54

Execution : Dry

ECONOMIC CAPSULE PRESSURE GAUGE

Compact design, Stainless steel case, Low pressure application (<0.6 mbar)

Dial size : DN63 / DN100 / DN125 / DN150

Range : -600...25...600 mbar

Process connection : ½" NPT (M) / ½" BSP (M)

Ingress protection : IP 54

Execution : Dry

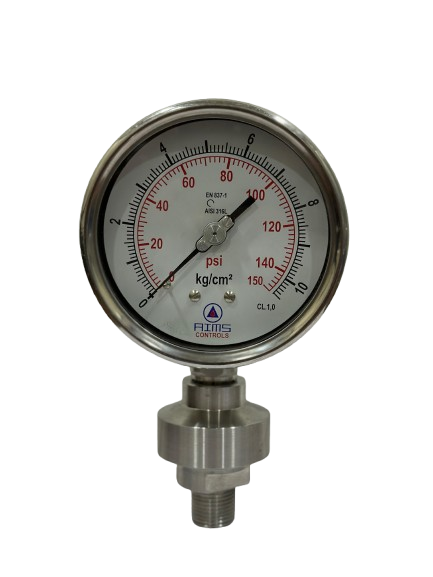

SANITARY SEAL PRESSURE GAUGE

Integrated gauge seal assembly, Laser welded diaphragm, Reduced vibration/pulsation

Dial size : DN50 / DN63 / DN100 / DN 150

Range : -1…40 bar

Process connection : 1½" Tri-Clover

Seal filling fluid : Glycerine [10°C to 150°C]

Execution : Dry but fillable, glycerin

HOMOGINIZER PRESSURE GAUGES

Laser welded diaphragm, Optional electric contacts, Optional transmitter output, Filled version

Dial size : DN100

Range : 0…160 bar, 0…250 bar, 0…400 bar, 0…600 bar

Process connection : With mounting flange

Seal filling fluid : Food grade oil

Execution : Dampening liquid filled, glycerine

PRESSURE GAUGE WITH WELDED DIAPHRAGM SEAL (THREADED)

Laser welded diaphragm, Full seal-welded seal

Dial size : DN100

Range : 4…70 bar

Process connection : ½" NPT (M) / ½" BSP (M)

Seal filling fluid : Silicon DC 200

Execution : Dry, IP 65

PRESSURE GAUGE WITH WELDED DIAPHRAGM SEAL (FLANGED)

Laser welded diaphragm, Full welded construction

Dial size : DN100 / DN150

Range : -1…400 bar

Process connection : 1½" RF 150# as per ANSI B16.5

Seal filling fluid : Silicon DC 200

Execution : Dry, IP 65

TEST PRESSURE GAUGE

Precision measuring system, High resolution dial markings, Knife Edge pointer, Anti-parallax mirror band, Jewel bearing movement

Dial size : DN 150 / DN250

Range : -1…700 bar

Process connection : ½" NPT (M) / ½" BSP (M)

Carrying case : Pine wood carrying case

Certificate : Calibration cert. traceable to Nat'l & Int'l standards

EDGE WISE DRAFT PRESSURE GAUGE

Economical version, Easy installation, Panel mounting style

Dial size : 150 x 78 mm / 200 x 104 mm

Range : -6,000…6,000 mmWC

Mounting pattern : Back connection with mounting bracket

Process connection : ¼" BSP (M)

Execution : Dry

SS CASE BRASS PRESSURE GAUGE

General purpose, Stainless steel case, Dry / liquid filled, Municipal water supply projects

Dial size : DN50 / DN63 / DN80 / DN100 / DN150

Range : -1...0...400 bar

Process connection : ½" NPT (M)/½" BSP (M)

Ingress protection : IP 54 / IP 65

Execution : Dry / Dry but fillable, glycerin

LOW DIFFERENTIAL PRESSURE GAUGE

Diaphragm operated Compact for Pharma Application

Accuracy : ± 2 % (Ascending)

Dial size : DN100

Range : 6 to 300mmWC or 60 to 1000 Pa or 0.25 to 250” WC

Mounting : Back / Side connection

Process connection : 1/8"NPT (F) X 2 Nos.

CAUTION NOTICE

It has come to our notice that certain unscrupulous persons are falsely claiming to be representing  / PI Controls Instruments Private Limited (our Company) and are posting false information by offering dealerships and other services on the Company’s behalf. Please note that we have never authorized any person or company to offer dealerships in our name.

/ PI Controls Instruments Private Limited (our Company) and are posting false information by offering dealerships and other services on the Company’s behalf. Please note that we have never authorized any person or company to offer dealerships in our name.

PI Controls Instruments Private Limited is the Sole Owner of Trademark,  . There is not any subsidiary anywhere in the world.

. There is not any subsidiary anywhere in the world.

The aforesaid wrongful use of our name/trademarks/fake materials violates our rights, and we disclaim all liabilities arising out of such dealings.

Members of the public and the trade are hereby cautioned against dealing with such unscrupulous persons and are requested to bring to our notice (at the below address) such wrongful activities to enable us to institute appropriate legal proceedings, both civil and criminal, to curb such activities. Please note that the correct website /domain name of the Company is https://www.picontrols.co.in and we would recommend checking the authenticity of each claim at the below contact details.

We endeavors to ensure that the data and other material in this section are correct and complete but does not accept liability for any error made or omission from this section.

We shall not be liable for any clPI or losses of any nature, arising indirectly or directly from use of the data or material on this section or unauthorized access to this section or otherwise howsoever arising (except to the extent required by law).

How to Detect Scams

1) Our officials do not communicate via generic email addresses such as Hotmail, Yahoo. All communications will always originate from a verifiable https://www.picontrols.co.in e-mail address (domains of @ picontrols.co.in) and not from any free web-based email accounts.

2) Fraudsters usually request targets to keep business proposals, etc confidential.

3) Fraudsters usually communicate only via email and telephone with a reluctance or a refusal to meet in person.

4) Conduct general searches (Google or https://www.picontrols.co.in Official website) to verify the details provided in false letters and communications.

How to Contact us

You should consider reporting the incident to your local law enforcement.